Formidable Tips About How To Build A Value Stream Map

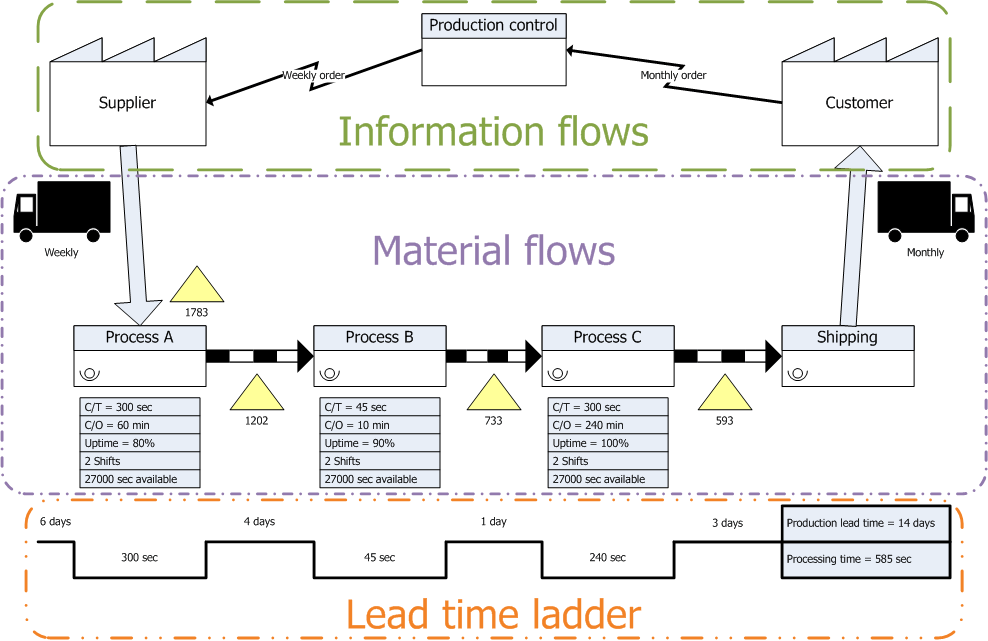

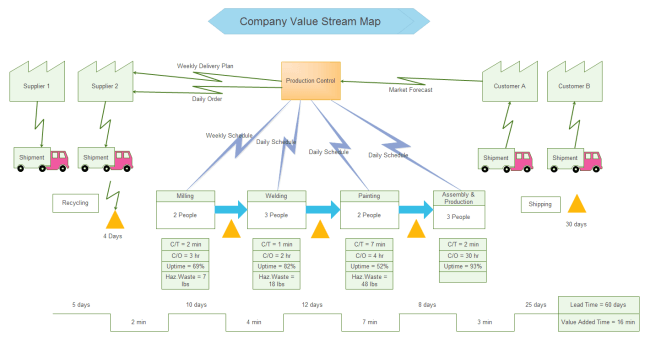

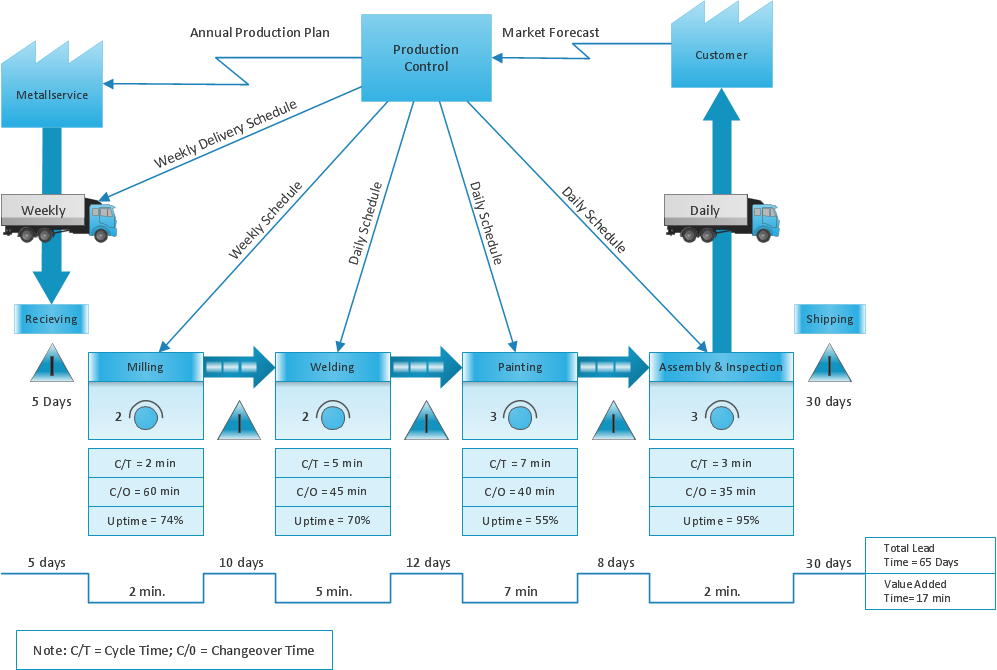

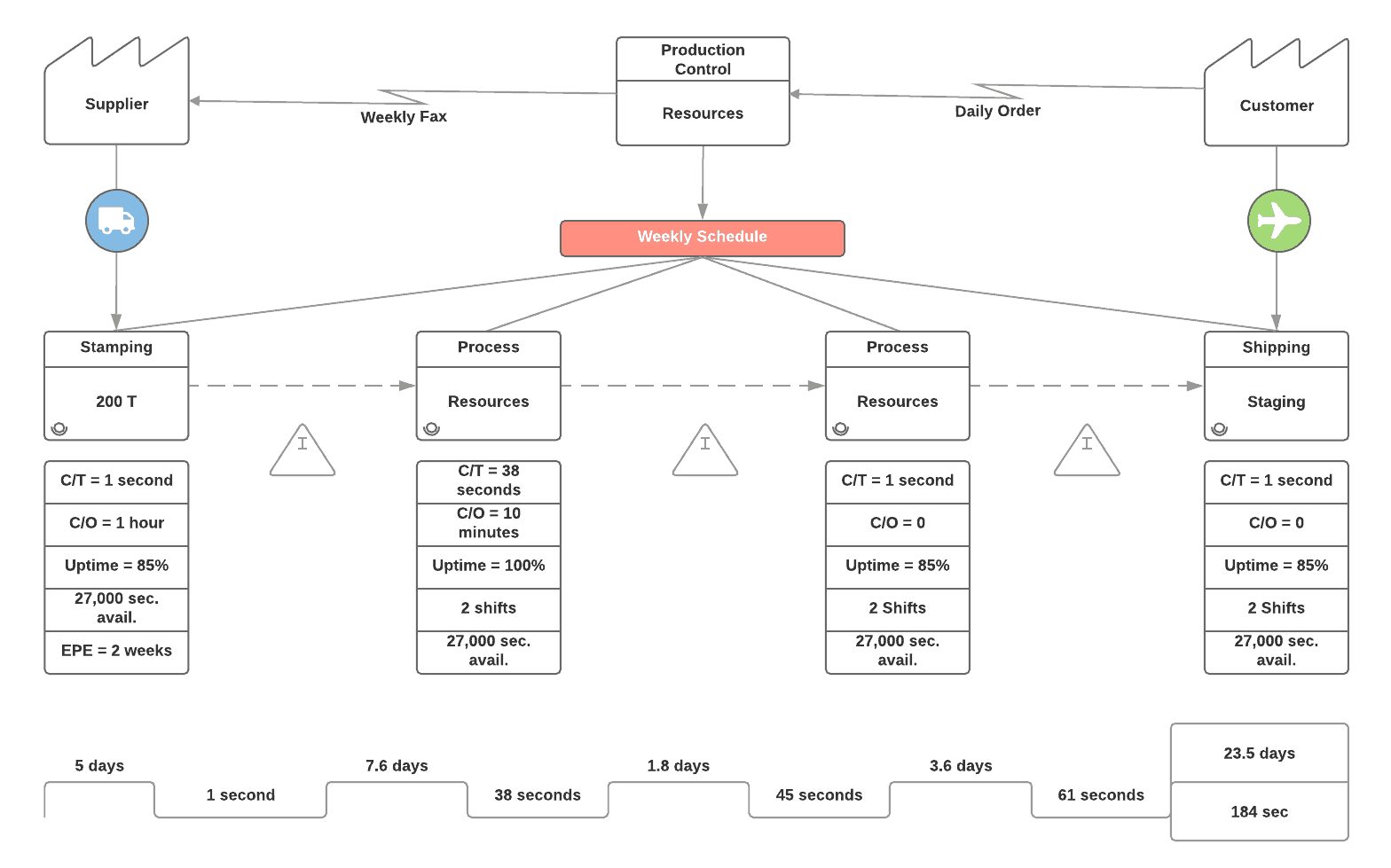

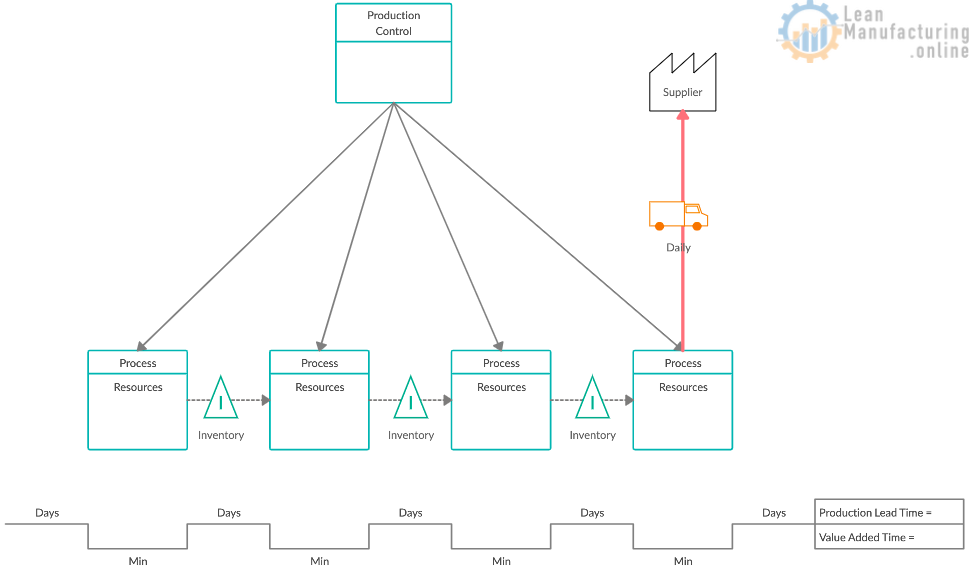

Value stream management (vsm) is a lean manufacturing process that focuses on improving the flow of materials and information through a process.

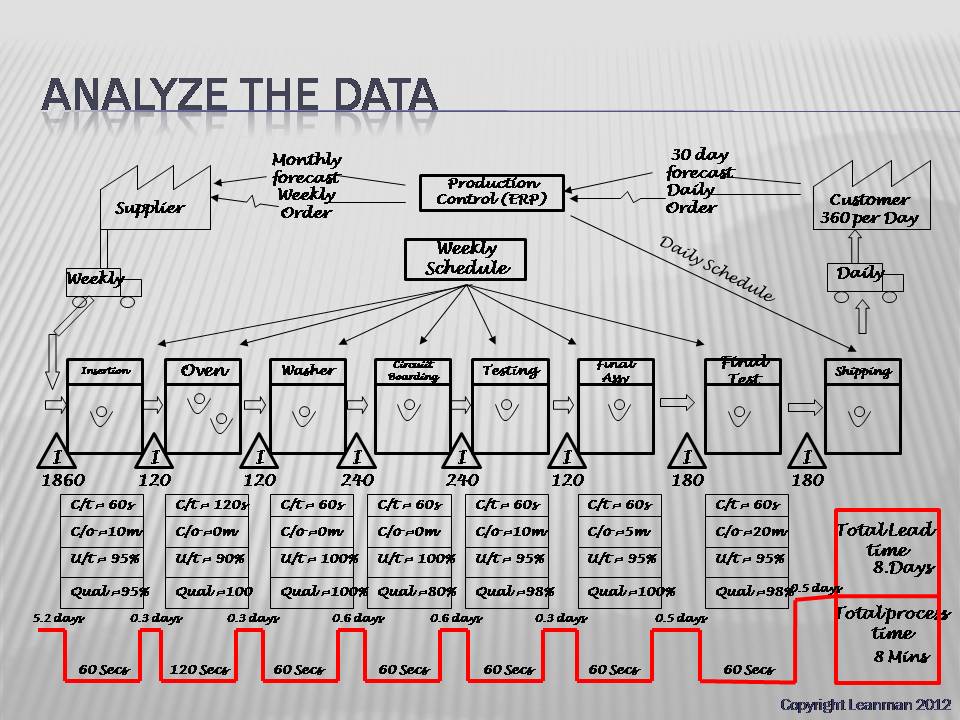

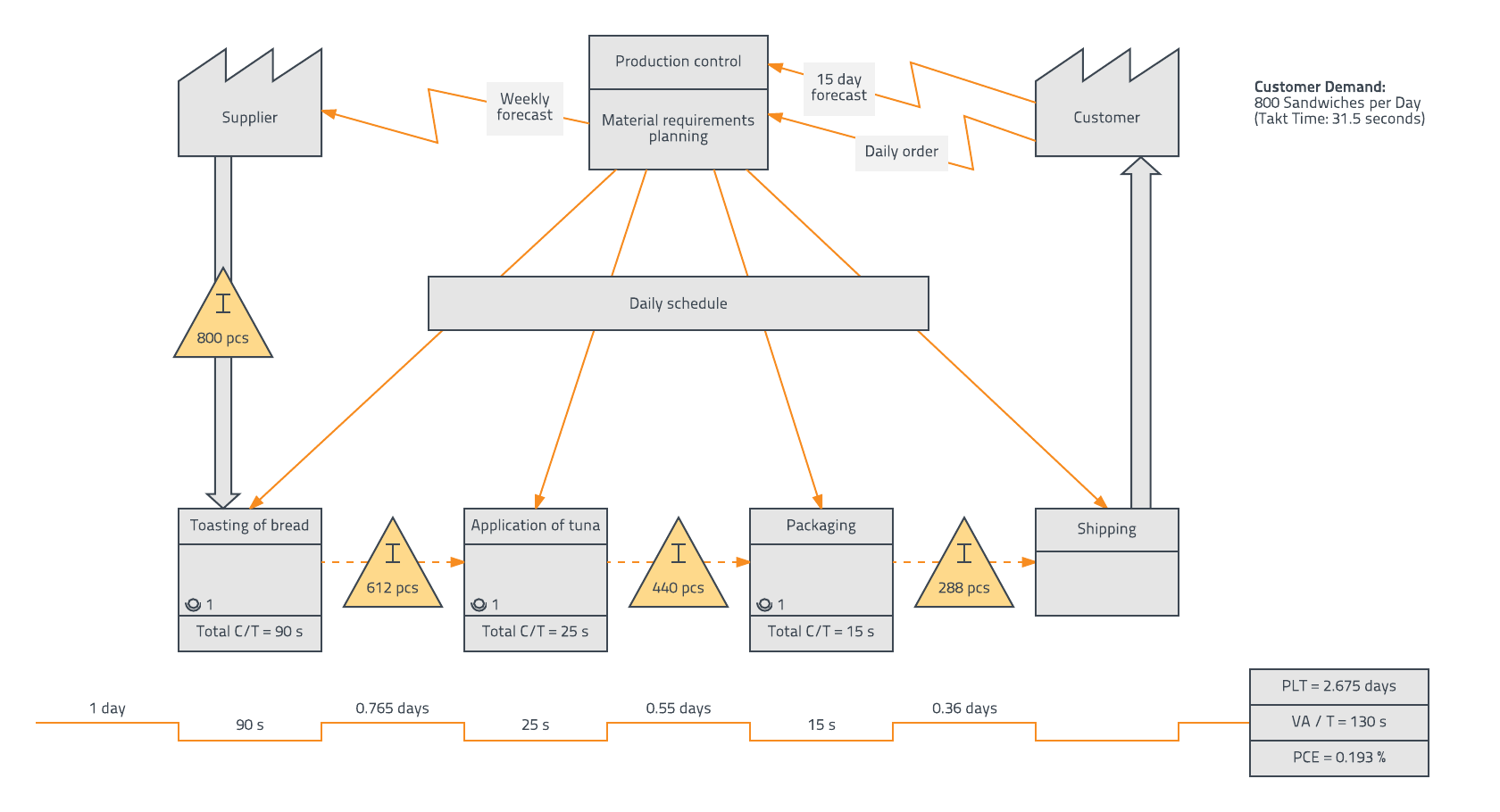

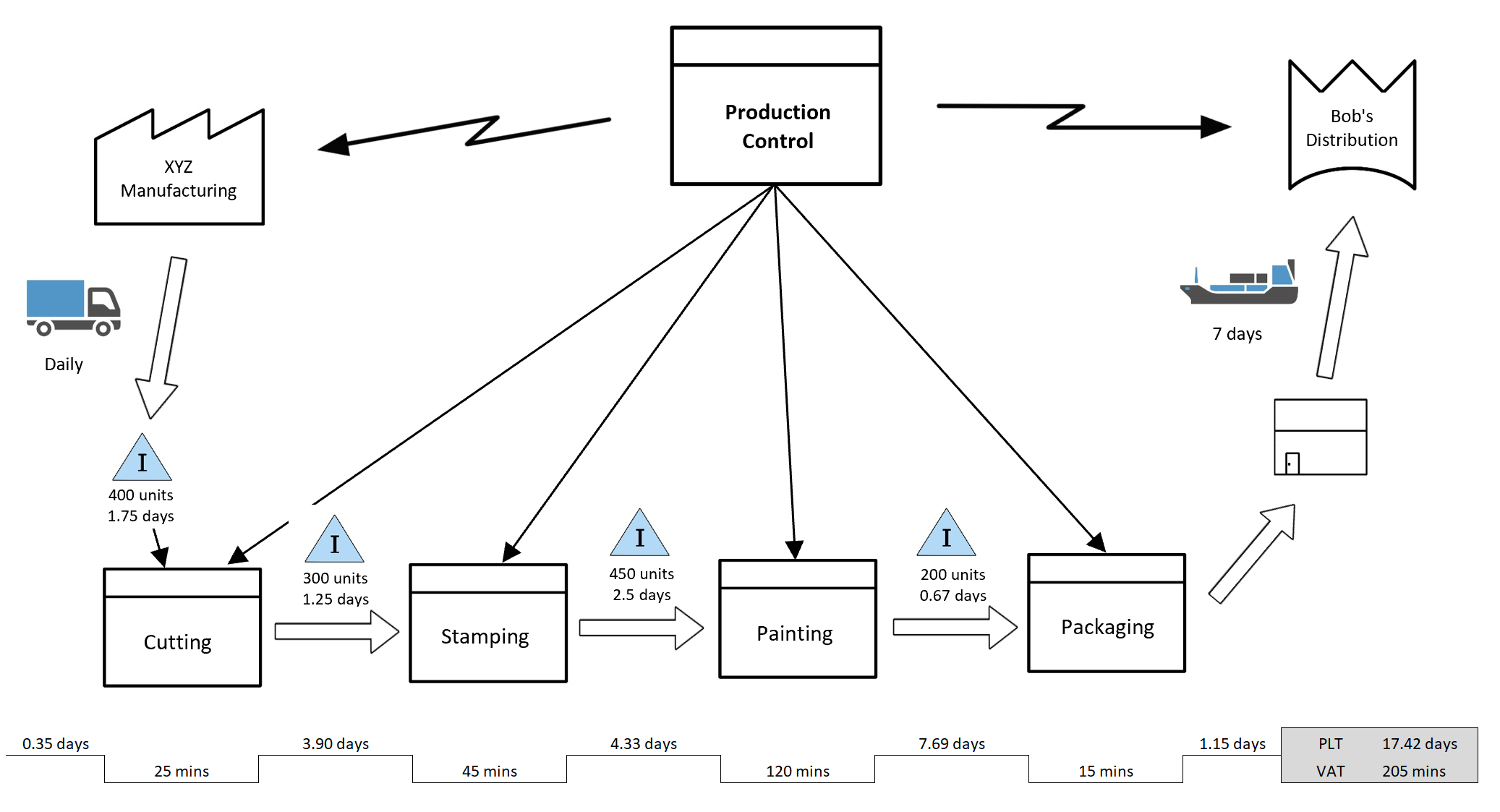

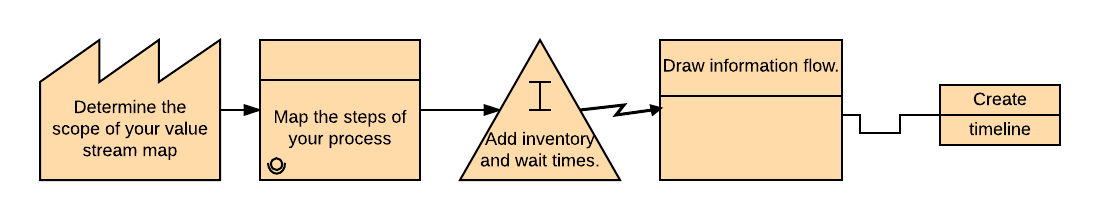

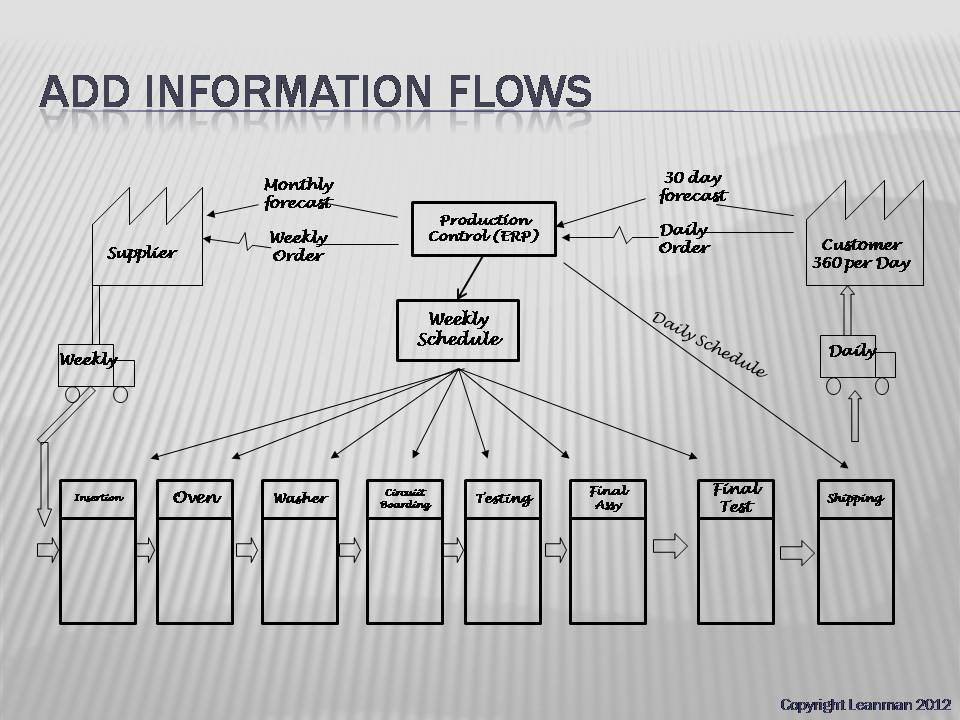

How to build a value stream map. If possible, observe and time the work. Once you have all the process and data boxes in, it’s time to add in inventory and/or waiting times. Design a balanced road map that will signal success and fund itself.

Decide how you’ll display the board for your team. Value stream maps also use a set of unique symbols to help teams visualize their operational processes. Value stream mapping (vsm) is a lean manufacturing technique used to analyze, design, and.

The value stream mapping process allows you to create a detailed visualization of all steps in your work. Select one value stream map template to. A value stream map illustrates the flow of materials and information from supplier to customer.

These are the little yellow triangles. It’s used to reduce costs, waste, and. 5 steps to build a kanban map.

With the expected value, cost, and impact timetable for each initiative in hand, and with a clear sense of. The value stream mapping, used typically in lean, comes with the fulfillment of the following purposes. Up to 24% cash back step 1:

If you’re using lucidchart to complete your diagram, make sure to use our value stream map template or add our value stream shape library. If it’s digital, input the same. In a value stream, valuable activities are shown separately from wasteful activities.